In the ever-evolving landscape of water and wastewater infrastructure management, the reliance on time-tested tactics remains paramount. As we navigate the complexities of maintaining and operating our built infrastructure assets, combining qualitative and quantitative data collection methods emerges as a steadfast approach to understanding and evaluating infrastructure condition. This blog article delves into the foundational principles that have stood the test of time, exploring the blend of qualitative insights and quantitative precision in condition assessment. Join us on a journey through the tried and true methods that have proven instrumental in ensuring the longevity, safety, and efficiency of our critical water and wastewater infrastructure assets.

Factors Impacting the Cost of Pipeline Condition Assessment

Water and wastewater utilities face the challenge of maintaining infrastructure that has served for decades. Buried pipeline infrastructure poses accessibility challenges from physical limitations and operational constraints. Consequently, utilities must strategize effectively to plan for potential rehabilitation or replacement initiatives. The optimal approach involves conducting a comprehensive field-based condition assessment, ensuring the availability of up-to-date and precise data for informed decision-making. However, the logistics of gathering condition data can be challenging, impacting the pipeline condition assessment cost.

Confined Space Entry Cost for Condition Assessment of Municipal Infrastructure Can Be Influenced by Various Factors

Metallic Corrosion: Methods for Assessing Structure Condition

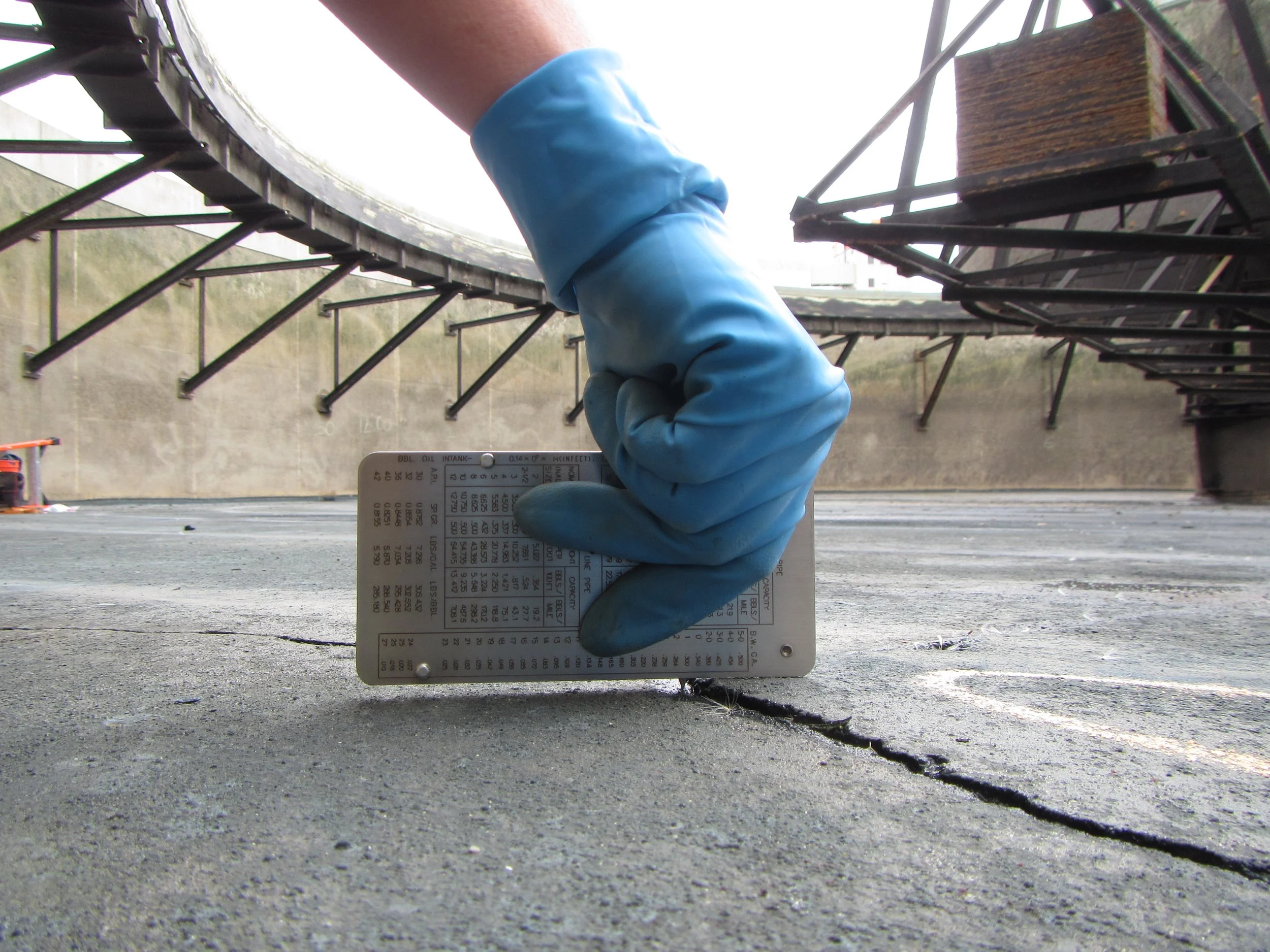

Metallic surfaces and structures commonly found in the water and wastewater industry include pipelines, gates, treatment plant basins, reinforcing steel embedded in concrete structures, access lids, and steel tanks. Metallic assets are critical components of water and wastewater systems; however, these assets are susceptible to corrosion which can be detrimental to system operations.

Engineers employ various methods to prevent electrochemical reactions from causing corrosion damage to metallic surfaces. Regular intervals of condition assessment are critical to evaluating metallic structure assets to identify and counteract corrosion before it becomes a costly and devastating problem.

Condition Assessment Methods for Reinforced Concrete Structures at Wastewater Treatment Plants

As wastewater treatment facilities age, it is critical that the concrete structures are assessed at regular intervals to identify and locate areas of degradation early, while a repair is still a cost-effective solution. To many in the wastewater industry, Condition Assessment is defined as the engineering analysis of structures and facilities to determine the remaining service life. Condition Assessment includes the use of appropriate and established tools and techniques to measure the current condition of a structure or facility against industry standards. For V&A’s engineers, Condition Assessment is performed by collecting quantitative data in the field to complement visual investigations.

Mechanisms of Corrosion in Reinforced Concrete Structures at Wastewater Treatment Plants (WWTP)

Reinforced concrete is one of the most common construction materials, especially in the wastewater industry. Concrete, in its most basic form, is a mixture of water, aggregates, cement and reinforcing steel. Concrete is strong in compression and very weak in tension which is the reason reinforcing steel is added to form a composite structure.

While concrete used in wastewater applications can be quite resilient, proper design and corrosion protection are necessary to ensure the structure lasts through its intended service life.

Measuring Coffee and Corrosion: What is the “best” cup of coffee, and what is “bad” corrosion?

C Factor Testing

Why am I seeing an increase in my energy use at wastewater pump stations? Pump stations are often designed using a Hazen Williams C Factor of 120 for new force mains. Over time debris and a slime layer builds up on the interior surfaces of wastewater force mains resulting in a reduction of the C Factor. As the C factor decreases the power required to pump the wastewater increases.

Southern California Steel Water Storage Tanks Condition Assessment

Our work takes us into spaces that are critical to our infrastructure. In this blog, V&A shares a view inside and outside of several steel potable water storage tanks located in Southern California. Take a tour with us and see inside and outside these massive steel structures. It is a view unlike any other.