Project Description

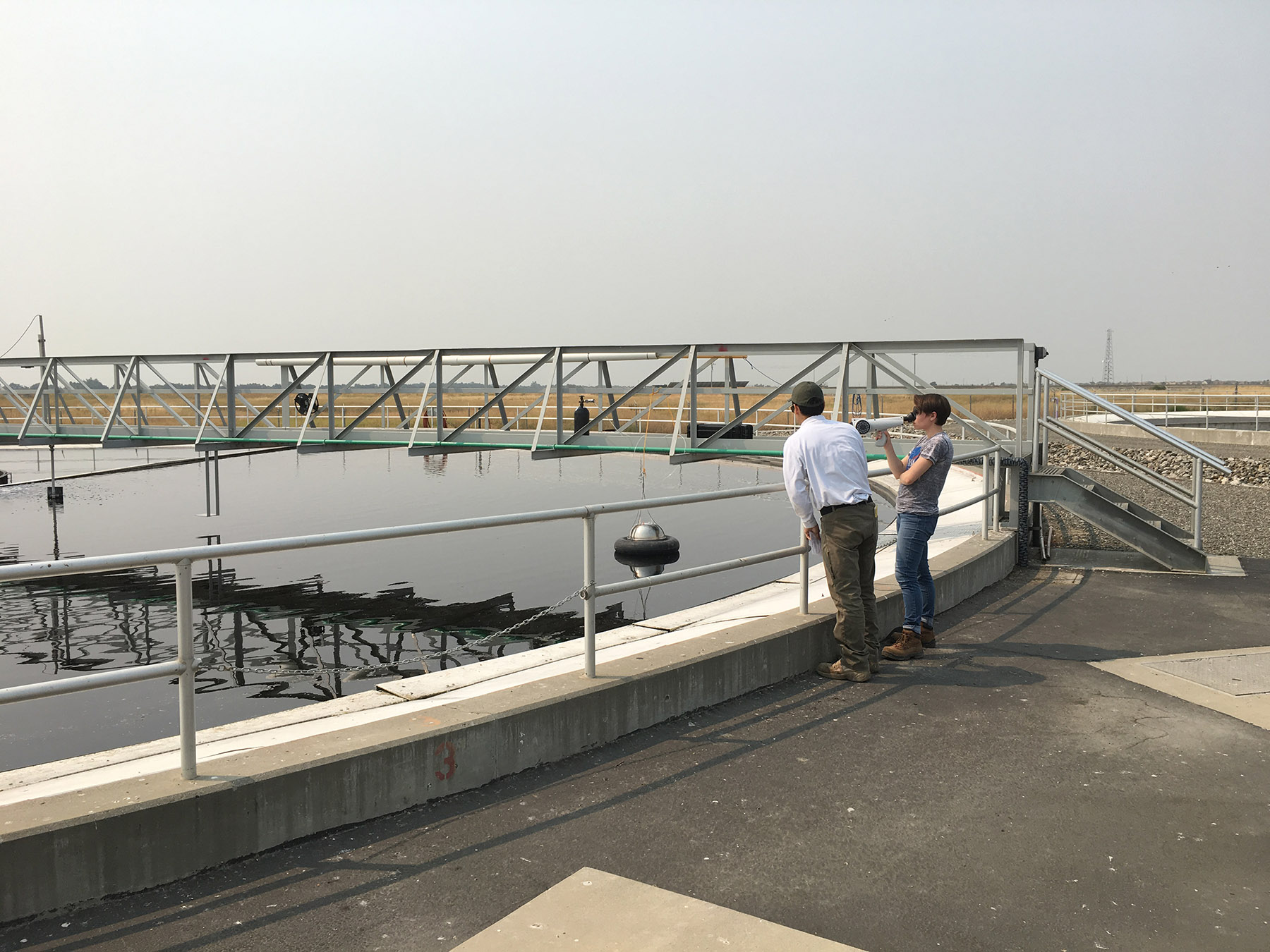

V&A performed condition assessments of process piping in support of the Yard Piping and Road Improvements Project (Project) at the San Jose-Santa Clara Regional Wastewater Facility (RWF). The purpose of the assessments was to obtain physical condition data on buried piping assets so that rehabilitation design and prioritization can be performed by the City of San Jose’s Environmental Services Department (City) and Black & Veatch Corporation (Black & Veatch), who serves as the Owner’s Advisor (OA) for the Project. V&A also helped establish a baseline for data collection, interpretation, and reporting for future Yard Piping assessments on the Project.

Condition assessment methods used to evaluate the piping included visual assessment with photo and video documentation, closed circuit television video (CCTV) with hydro-jet cleaning, lining assessment, concrete sounding, concrete penetration measurements, surface concrete pH testing, surface penetrating radar, and concrete coring. Due to the crown corrosion from biogenic corrosion that was observed, V&A also took dimensional measurements to help quantify the extent of damage.

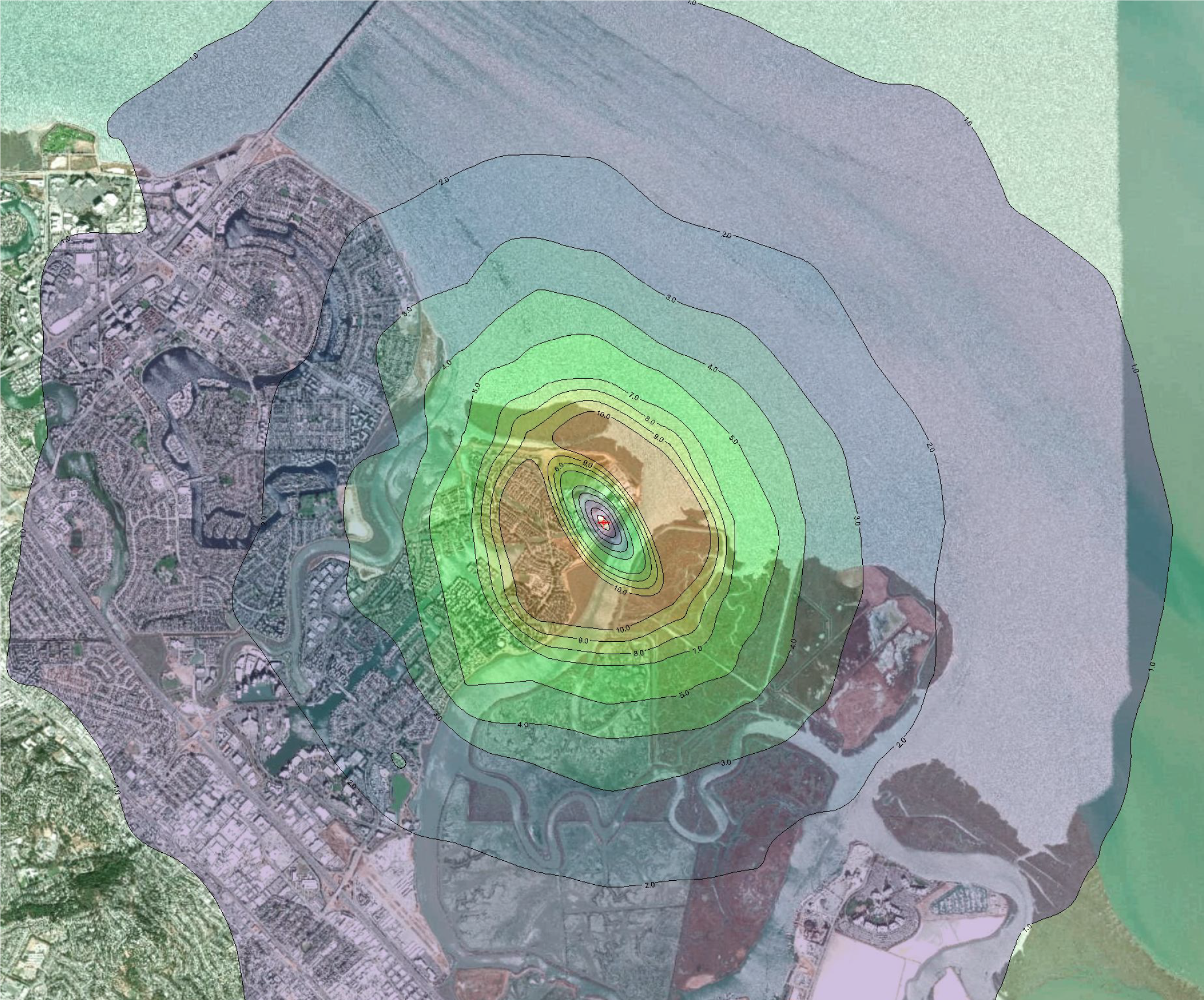

The results of the field investigation were analyzed and utilized to develop overall pipe condition ratings. Pipe condition ratings were based on a scale between 1 and 5, with 1 being new or excellent condition and 5 being failed or imminent failure. These ratings were used to estimate the remaining service life of the piping as well as to help prioritize repair and rehabilitation needs.

Assessment, Design and/or Construction Challenges and Solutions

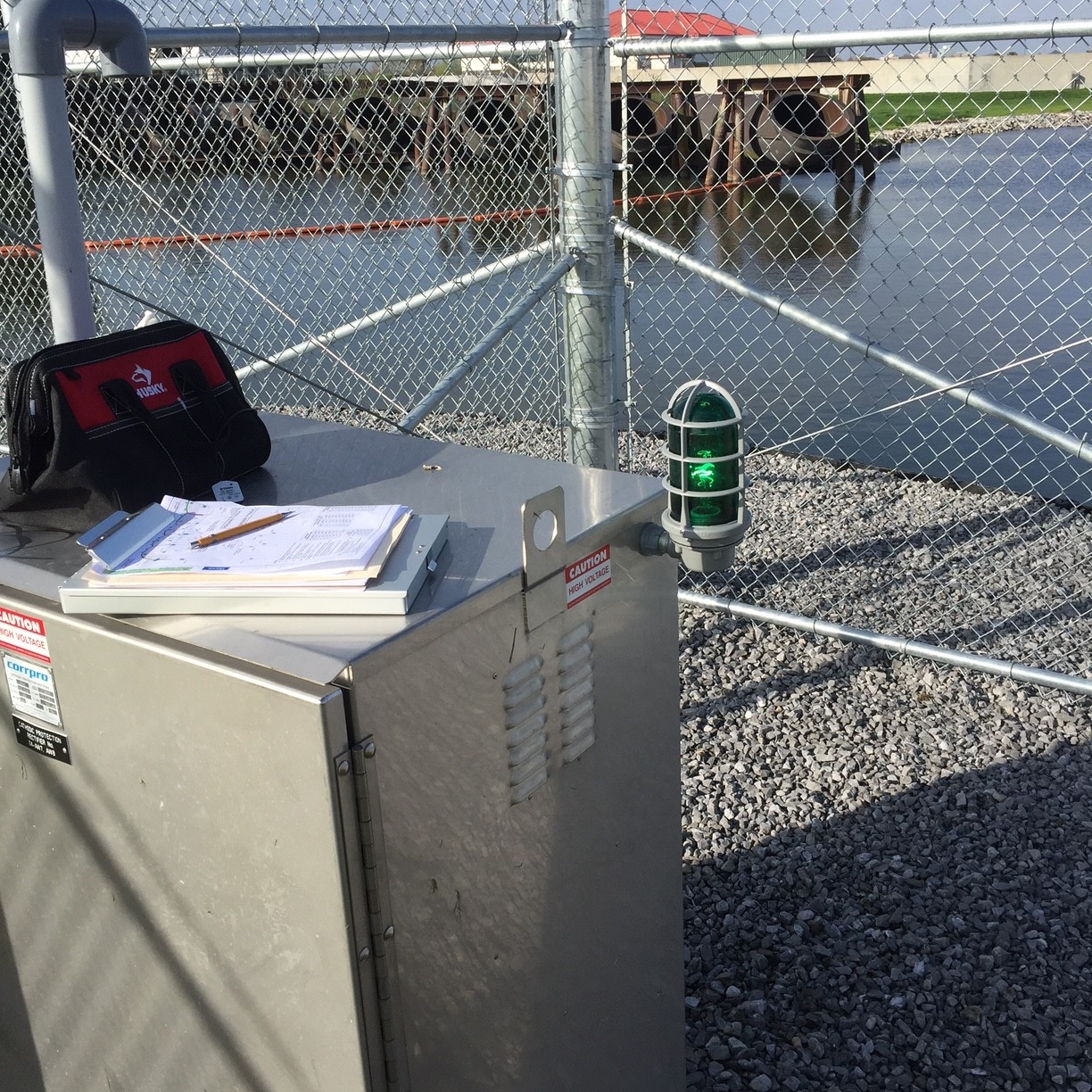

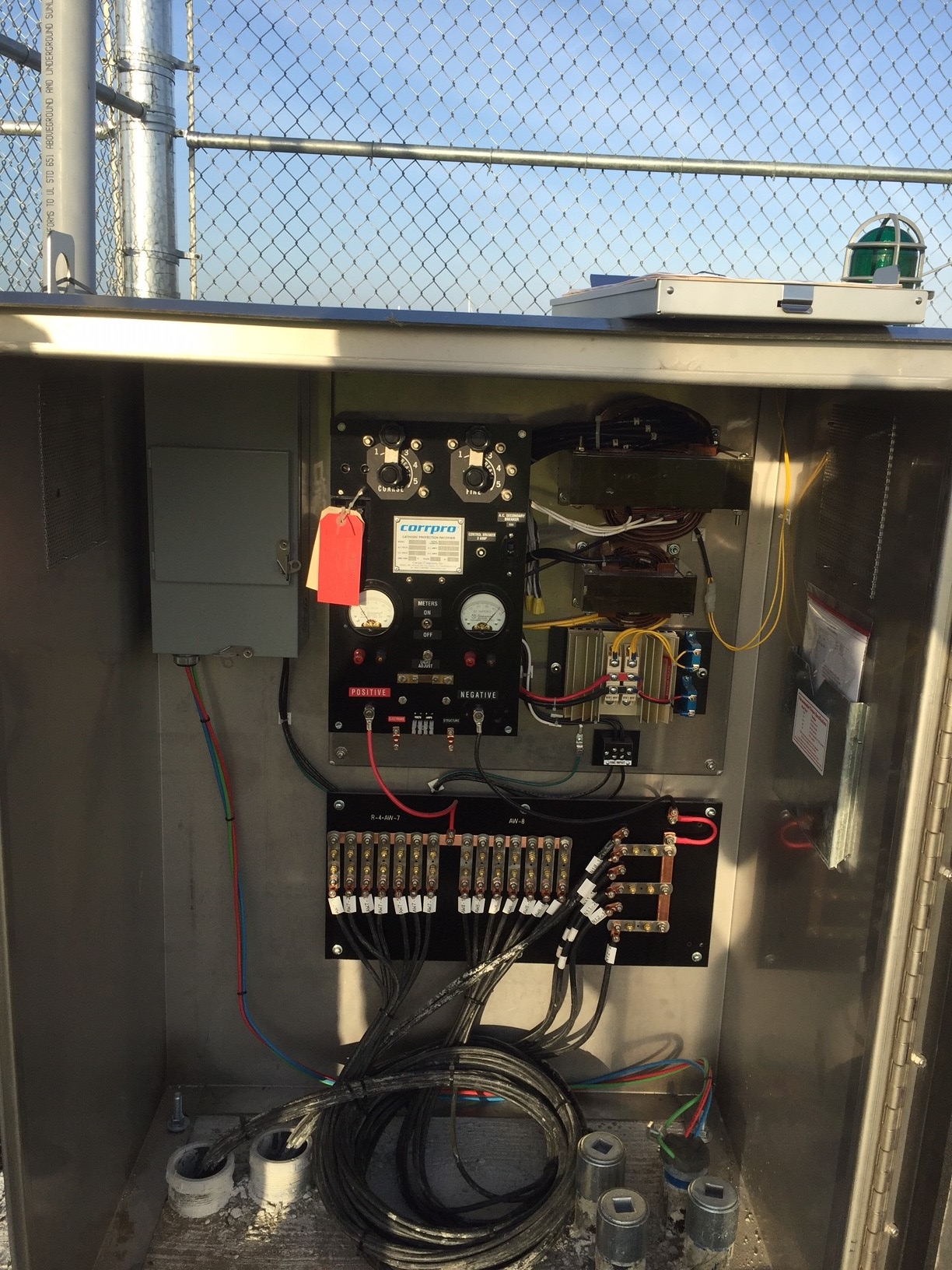

V&A prepared a safety plan to mitigate risks and to outline procedures to be implemented during confined space entry work related to the Yard Piping Condition Assessment at the RWF. As with all projects, safety is of the highest priority and is an integral part of our work. V&A’s confined space trained engineers conducted the field investigations with onsite confined space entry and rescue support from Lee & Associates Rescue, Inc. (LAR) and/or Jamison Engineering Contractors, Inc. (Jamison).

In order to ensure consistent data collection and reporting on the project going forward, V&A worked closely with the Black & Veatch and the City to develop a pipe rating index system based on the National Association of Sewer Service Companies (NASSCO) Pipeline Assessment and Certification Program (PACP). The pipe rating index system allowed V&A to assign defect grades and overall pipe ratings to individual pipe segments, and ultimately correlate the ratings to an estimated remaining service life.