“Poseer un negocio. English translation: Own a business. Words of my mother since I was 6 years old. I always knew my work would fill a large part of my life and it does. I love that.

”

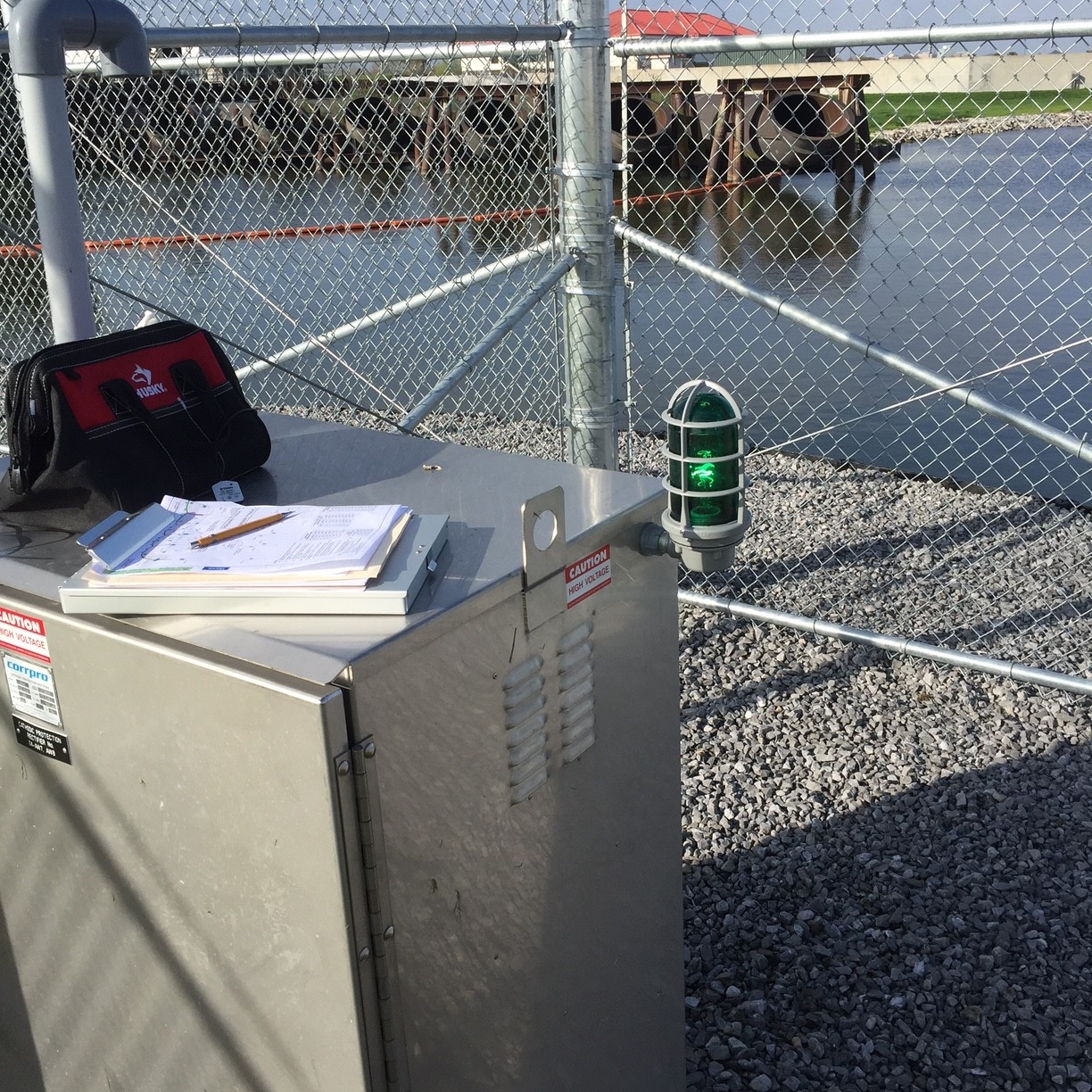

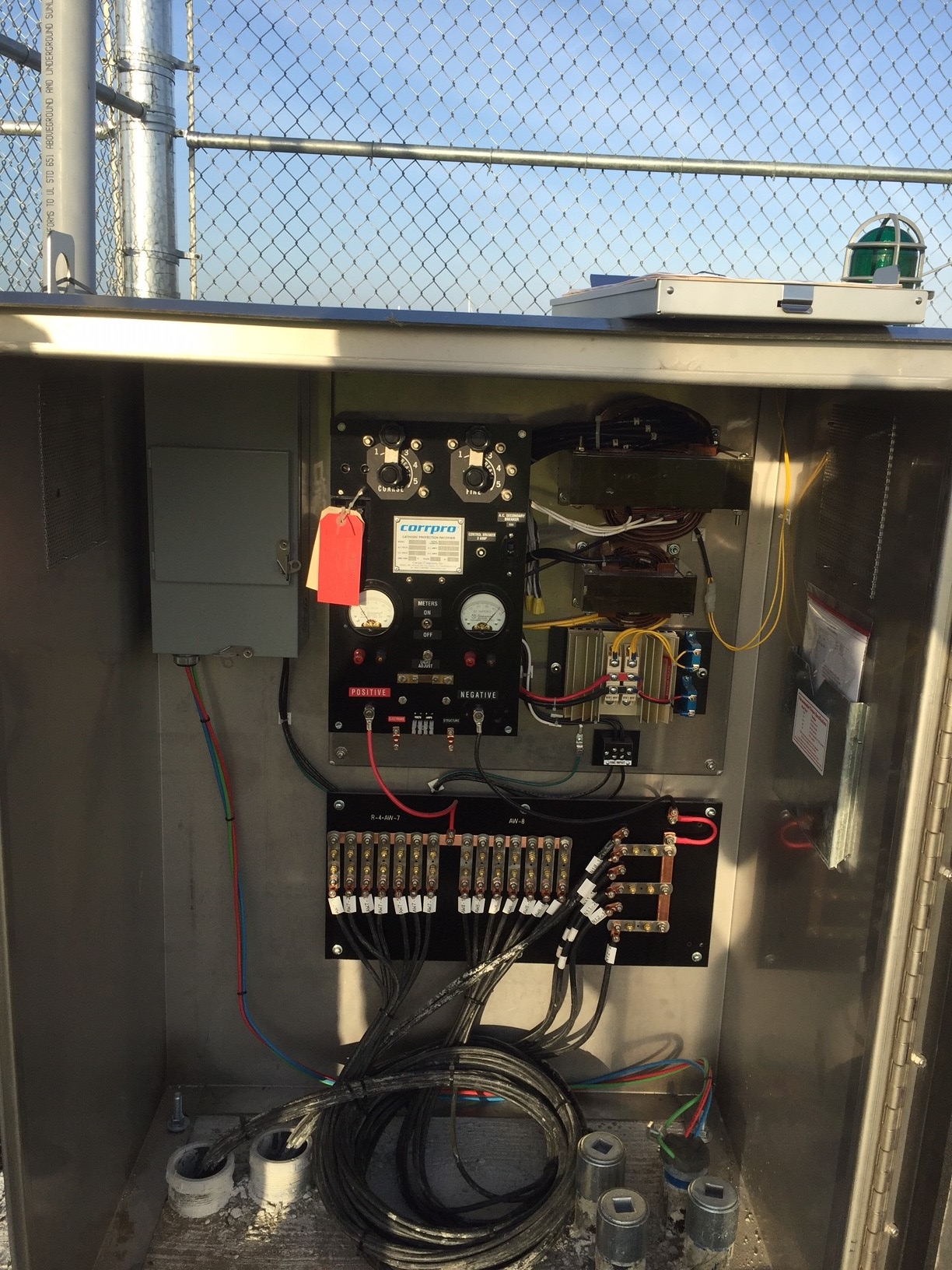

In 1979, our founder, José Villalobos, felt there was a need for an experience-based engineering firm that prioritized client service. His original services included corrosion engineering, civil engineering, and industrial waste treatment. He found that he could differentiate the firm by focusing on corrosion engineering with a specialty in evaluating, rehabilitating, and preserving municipal infrastructure. The first office opened on Commercial Street in Palo Alto, California and our clients included many cities, special districts, and contractors in the Bay Area. By 1982, we moved to a larger space in the historic Old Alvarado Hotel in Union City. In 1987, further growth prompted another move, to Oakland, where our corporate headquarters remain. Providing a valued service to the market allowed for our expansion to other cities – Houston, Texas; San Diego, California; Las Vegas, Nevada. This year marked the opening of offices in San Antonio, Texas and Lakewood Ranch, Florida where we will continue to offer our specialized services to both existing and new clients.

When hiring that first employee in 1980, we knew that creating a fulfilling and supporting environment for our staff would be critical for the success of the firm. Our early company foundation notes included a pledge to create a firm where engineers can enjoy challenging work and grow their expertise; and have a fun and engaging work environment. Our dedication to our employees continues to this day with a commitment to a strong company culture grounded in our core values of honesty, integrity, respect, commitment, loyalty, and quality.

One of the most rewarding things about being in business for 40 years is the strong relationships we have built with our clients over those years. We are working together to improve our communities and to protect public health and the environment. As our infrastructure ages and new challenges arise, we look forward to the continued partnerships. We are proud of this milestone anniversary and look forward to what we will learn in the next 40 years!

Looking back . . . José Villalobos